FILMAX IS PROUD TO OFFER AIR SENTRY® GUARDIAN BREATHERS

Air Sentry® set the industry gold standard with their first line of contamination control breathers in 1997, and today that standard is raised with the introduction of GUARDIAN. Air Sentry® was the first to integrate check valve technology into a desiccant breather; being the first to offer replacement cartridges was another significant stride in reducing costs for customers. Now, GUARDIAN takes check valve technology and cost-saving replacement measures to the next level. Air Sentry also introduces four exclusive advancements that will again raise the bar in contamination control

TRITAN™ CONSTRUCTION

GUARDIAN is the first breather constructed of Tritan™. This patented material is the most chemical-, temperature-, and impact-resistant combination casing on the market.

ISOLATION CHECK VALVE

GUARDIAN is first again with an isolation check valve, which isolates the adsorbent from exhaust air to lengthen service life of the desiccant while also protecting it from volatile and splashing fluids.

INTEGRATED COMPOUND VACUUM / PRESSURE GAUGE

This proprietary feature is a true-life accurate indicator of filter conditions.

STACKABLE

Stack cartridges to extend the life of breathers even further using the Modular Stack Ring™

This proprietary feature lengthens the service life, reducing costs and maintenance intervals.

Air Sentry® Contamination Control Breathers replace existing breather caps or air vents on fluid-holding tanks, reservoirs, and gearboxes. Older air venting methods provide minimal, if any, contamination control. Air Sentry® breathers provide the first line of defense in contamination control methodology, utilizing patented designs and featuring color-indicating silica gel and self-cleaning 2-micron filtration.

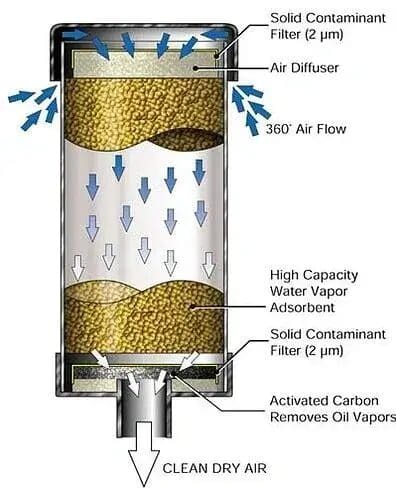

Diagram 1

Indicates how our patented design allows outside air to enter through the 360° opening in the breather's top cap. The top cap design overhangs the body of the breather, helping protect the breather from rain, sleet, snow, and most equipment wash-down procedures.

When contaminated air enters the top of the breather, it passes through a self-cleaning solid particle filter. This filter traps solid particles greater than 2 microns and keeps them from entering the breather and, ultimately, to wear surfaces on your equipment. The filtered air then passes through a bed of silica gel that adsorbs moisture in the air. During this step, up to 95% of water vapor in the air is filtered out.

Finally, the filtered air passes through an additional 2-micron filter in the bottom of the breather to ensure that no harmful particles will enter the tank or reservoir. This three-stage filtration design ensures your equipment gets CLEAN, DRY AIR!

As the color-indicating silica gel adsorbs moisture, it changes from gold to green. When the silica gel is adsorbed to its capacity (approximately 40% of its original weight), the breather will become entirely dark green. This color change is easily seen and serves as a visual indication that it is time to remove and replace the disposable breather.

Guardian Overview

Diagram 2

Indicates air being expelled back through the desiccant breather from the equipment on which the breather is mounted. As contaminated air travels this reverse path, expelled water vapors are adsorbed by the silica gel.

During this reverse air flow process, the silica gel indicates the presence of excessive moisture inside the reservoir as the gold silica gel turns dark green from the bottom of the breather rather than from the top of the breather.

An additional feature located at the bottom of most Air Sentry® models is a layer of carbon-impregnated foam. This carbon pad absorbs small amounts of oil vapor exhaled from the tank and protects the silica gel from minor oil mist contamination. Excessive oil mist control may be required, and adapters are available for applications with excessive oil mist problems.

As the exhausted air passes back through the self-cleaning 2-micron filter located in the top cap of the breather, any trapped particles are now flushed back from the filter.